What Stainless steel to use for Marine and boating applications

From the wooden ships of the vikings to 200,000+ tonne modern cargo ships, the innovation of sea travel has been quite incredible over the last few hundred years; and one modern innovation is the use of specialised grades of Stainless steel to build boats that can weather even the toughest of ocean conditions, ensuring the lifetime of the vessel is decades long with minimal maintenance.

Commonly used today in the construction of marine vessels are Stainless steel and aluminium. While aluminium is light, it has limited corrosion resistance in seawater and requires significant maintenance, whearas Stainless is recognised as the premium material for marine applications.

Keep reading to see which Grades of Stainless steel are ideal for marine use, our product range, and examples of our Stainless in use in impressive customer vessels.

One of the Cape class vessels for the Royal Australia Navy, fabricated by Austal with Stainless steel supplied by Stirlings.

Types of Corrosion in Marine Environments

Example of seawater corrosion on a buoy.

Seawater is so corrosive is due to its salinity, meaning that it contains chloride ions. In Stainless steel, these ions result in the penetration of the chromium passive layer in localised areas and reacting with the iron underneath causing oxidation, also known as pitting corrosion. This corrosion is even more severe in crevices where the chloride irons can build up over time, along with biological matter such as barnacles. Stress corrosion cracking can also occur under certain conditions, including in wet diesel exhausts and other areas. It is vital therefore to employ specialised grades of Stainless to withstand these conditions.

We have a full blog on Stainless steel oxidation here.

Pitting Corrosion

Pitting corrosion is a localised attack of weakened parts of the protective film in stainless alloys, in a sense catalysed by chloride ions in water.

The temperature and chloride concentration both directly influence the onset, and to a lesser extent the kinetics, of pitting corrosion in Stainless steel, as shown on the graph below. The composition of different Grades will be affected differently - as seen below, Grade 304 has the lowest level of corrosion resistance in these conditions, whereas Grade 2205 (S32750) has the highest out of these Grades.

Graph of pitting corrosion in marine applications, in different Grades of Stainless steel.

Source: ASSDA

Crevice Corrosion

Crevice corrosion refers to the attack of metal surfaces by a stagnant solution in crevices, for example around the edges of nuts and rivet heads, or at propeller shaft glands and bearings where bolts and chainplates pass through the hull or deck. In marine environments, the electrochemical concentration of chlorides is higher on the inside of the crevice as opposed to the rest of the environment, which worsens the corrosion. It is in essence a more severe version of pitting corrosion.

Stress Corrosion Cracking

Stress corrosion cracking (SCC) is the catastrophic cracking induced from the combined influence of tensile stress, elevated temperature for most affected alloys, and a corrosive environment. For basic austenitic grades, this can be an issue in warm tropical waters, although Duplex grades and more highly alloyed austenitics are unaffected.

In marine environments, chains and other mechanisms may be subject to this type of corrosion, which can have severe effects on durability and structural integrity.

Types of Stainless used for Marine applications

Incat Hull 090, or the Bellarine Express, is a 35m wave piercing catamaran constructed by Incat Tasmania, with Stainless steel supplied by Stirlings.

U-Bolts in our Instore Shop.

Austenitic

The current industry standard for Stainless steel is Grade 316 - commonly termed "marine grade" Stainless, which offers a solution to around 90% of marine applications, although care in specification is required to ensure long term durability – “marine grade” can sometimes be seen erroneously as a panacea. The 2% molybdenum in Grade 316 works to further improve the corrosion resistance compared to Grade 304. 316L Stainless steel is almost identical to 316, the former offering improved weldability.

304 and 316 are workhorses in the marine industry and used in many forms for a plethora of applications: handrails, winches, ropes, chains, fasteners, claddings, ladders to name a few. More frequently installed in an electropolished surface finish, to eek out every drop of corrosion resistance although still require ongoing maintenance to look as new.

Nitronic 50 Stainless steel is an austenitic Stainless steel renowned for its exceptional resistance to corrosion, wear, and galling not found in any other commercial material available in its price range. It has almost double the yield strength of Grade 316 at room temperature, and corrosion resistance comparable to duplex alloys. Generally used as bar and forgings for shaft applications, including in precision ground form.

Precipitation Hardening

Precipitation hardened, PH, alloys are used whenever a particular combination of high strength, corrosion resistance, and toughness is required. After heat treatment they can give tensile strengths about three to four times stronger than the common austenitic Stainless steels such as Type 316L.

Duplex

Duplex Stainless steels offer a superior corrosion resistance to austenitic and Precipitation hardened Stainless steels. The three most common types in marine applications are 2304 (UNS S32304), 2205 (UNS S31803) and 2507 (UNS S32750). Of these the most common is 2205 - some benefits of 2205 include:

Yield strength twice that of 304 or 316;

Much higher resistance to pitting and crevice corrosion in seawater than Grade 316; and

Twice the fatigue and corrosion fatigue strength of 316.

Offering significant benefit at minimal to no cost (financial, and formability), its prevalence has grown widely across most applications where 304 and 316 have historically been used.

Super Austenitic

A super austenitic Stainless steel is considered to be an austenitic Stainless steel with a Pitting Resistance Equivalent Number (PREN) greater than 40. This is usually attributed to alloys with high additions of molybdenum, typically 6% or greater, along with newer alloy versions increasing nitrogen content as well.

Alloy 6Mo contains at least 6% Molybdenum. 6Mo is known for excellent thermal & electrical conductivity, excellent impact toughness, very high resistance to chloride corrosion, highly resistance to pitting, crevice and general corrosion as well as excellent workability & weldability. 254SMO is a well known alloy, with AL6XN also commonly used.

Alloy 926 is a super austenitic Stainless steel (containing 6-7% Moly) that also exhibits excellent resistance to a variety of highly corrosive environments. The combination of Molybdenum and nitrogen in its composition resists pitting and crevice corrosion, while copper improves sulfuric acid resistance, and nitrogen improves yield and tensile strengths.

So which do I choose?

The key to obtaining optimum results from Stainless steel is the use of the appropriate Stainless steel for the specific application. The below will provide guidance on the different levels of corrosion resistance that different grades offer and thus their applications, and our friendly team is here to advise further.

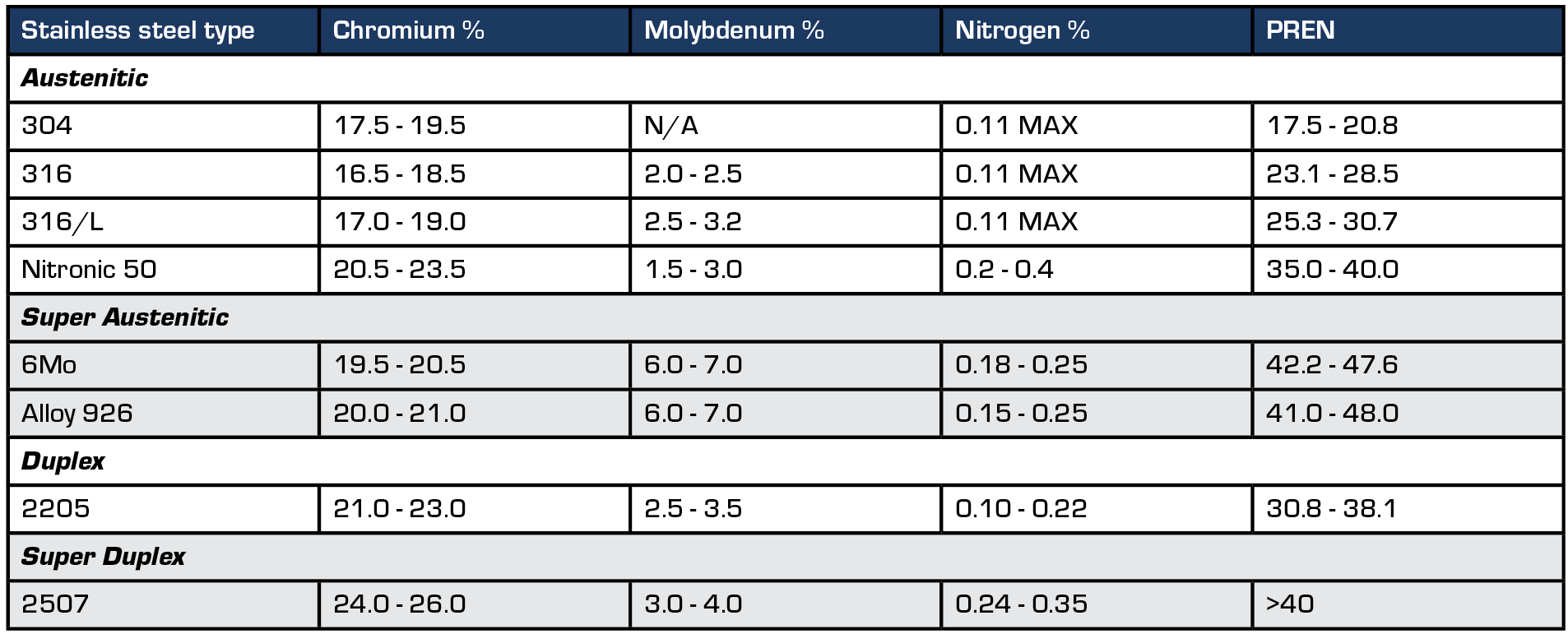

PREN Guide

The Pitting Resistance Equivalent Number (PREN) gives a guide on Pitting resistance for Stainless steels that contain chromium, Molybdenum and nitrogen. The higher the PREN, the better the resistance against pitting corrosion. The equation is as follows:

PREN = 1*Cr% + 3.3 * Mo% + 16 * N%.

Use Guide

Our product range:

We supply to a great range of different superyachts, ferries, patrol boats, defence vessels, catamarans, fishing boats and more - so we know exactly how to supply the right Stainless steel for your vessel! We have a great range already in stock and anything we don’t have we can provide from our well-established global supply chain.

We stock Stainless steel in the following commonly employed marine Grades:

Grade 316

Grade 316L

Duplex (2205)

Super Duplex (2507)

We can also supply other high-performance Grades and Nickel-based alloys on an Indent basis, including all mentioned earlier, and in any product form or volume.

We have a full range of Stainless steel products available for marine use, including:

Pipe & Pipe Fittings

Flanges

Tube & Tube Fittings

Sheet & Plate

Bar

Valves

Fasteners

Hygienic Fittings

Balustrade Fittings

Browse our Products section to view more, and contact us with any questions and to place an order.

Customer examples

All of these impressive vessels were fabricated with a range of Stainless steel parts from Stirlings - and this is only a sample of our extensive work with marine projects!

Click on one or more of the images below to get the specs and fabricator details.

A rhyme for your time

Worried about what you need for all things boats and marine? Our service and products at Stirlings - they’re sure to make you serene!

Sources

Corrosion Pit to Crack Transition Behavior of 304 Stainless Steel in a Chloride Solution - Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Representation-of-stress-corrosion-cracking-of-304-SS-in-ferric-chloride-solution-i_fig16_357893331 [accessed 1 Dec 2024]