The BEST material for Water Bore Casings and why: Schedule 20 Stainless steel Pipe

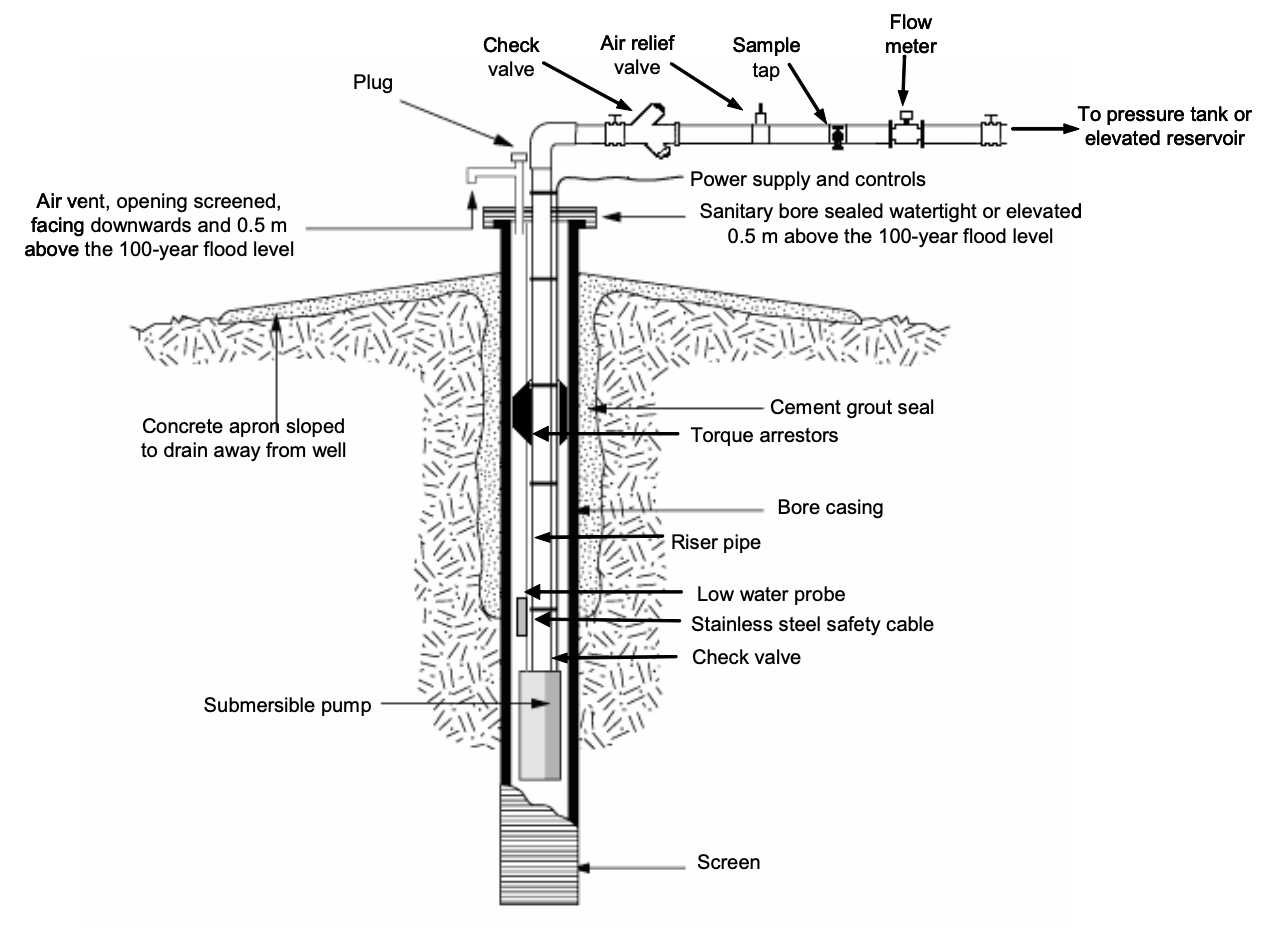

What are water bore casings?

Water bores are wells drilled to access water from an underground water body, known as an aquifer. These are both incredibly common and valuable in supplying ground water (for process or potable purposes via further treatment) in remote and inland parts of Australia.

Bore casings are pipes (PVC, concrete, mild steel or Stainless steel), and are incredibly important to maintaining the structural integrity of drilled shafts.

They are installed inside the borewell, and their purpose is to protect the internal diameters of the drilled shaft, and prevent the sides of the borehole from collapsing during drilling. This casing contains the pump that draws water from the aquifer and acts as a barrier, preventing contamination. The space between the casing and the borehole wall helps to maintain stability and prevents collapse.

Some water bores do not employ casing - however in these cases, the risk of collapse and contamination is significantly increased.

The benefits of bore casings

The use of water bore casings provides several benefits, including:

Protection and stabilisation of the water bore

Casing pipes can prevent contamination of the groundwater source. Without casing, there is a risk of surface runoff, chemicals or debris seeping into the well, however with bore casing, the risk of contamination from external sources is significantly reduced. They also play a significant role in preventing damage to the aquifer - the underground layer of permeable rock that yields water. Without proper casing, the drilling process may inadvertently disrupt the aquifer, compromising its ability to supply water. In addition, casing pipes provide structural support, preventing cave-ins and maintaining the integrity of the well structure, prolonging the lifespan of the borewell.

Facilitating the Pumping Operations

Casing pipes facilitate pumping operations by providing a channel for extracting groundwater from the well. The casing extends from the surface down to the desired depth, allowing for the installation of pumps and other extraction equipment.

Casing Material

Generally, the options for bore casing materials are PVC plastic, concrete, mild steel, and Stainless steel.

PVC plastic and concrete offer the most cost effective solutions in the short-term, and have good corrosion resistance, however their stiffness levels are inferior to mild steel. Mild steel offers greater strength and durability, however it is subject to corrosion over time in the conditions of a borewell.

Stainless steel solves all of the issues presented by these materials. With the strength and durability of mild steel and the excellent corrosion resistance comparable to PVC plastic and concrete, it provides an all-in-one solution to bore casing requirements. Stainless steel does come at an initial price point higher than its alternatives, however in the long term, it is much more cost efficient as it rarely needs replacement or maintenance.

Historically drillers and installers have been limited in choice to Schedule 10 and Schedule 40 wall thickness pipe in 316/L stainless steel, based on stock availability. Often, the opportunity to optimise casing design and reduce material and installation cost is lost

Schedule 20 Pipe

Schedule 20 Pipe is the ideal strength for bore casing, and the wall thickness is thinner than Schedule 40; so it costs less while performing the same job.

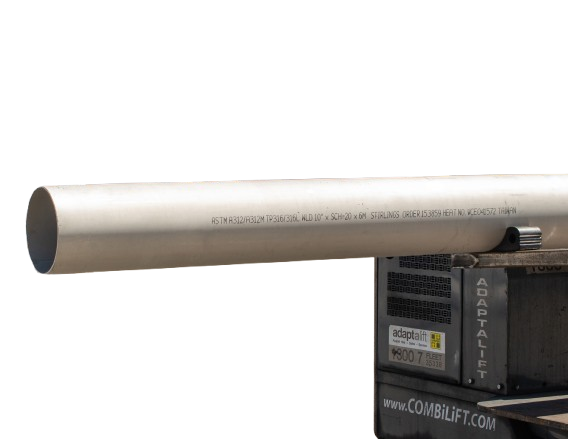

Schedule 20 Pipe in stock at Stirlings.

We are now locally stocking 316L Schedule 20 Stainless steel ASTM A312 Pipe in most commonly used diametres for your water bore casing requirements. Other sizes and grades are available on a mill production basis via our established global supply chain.

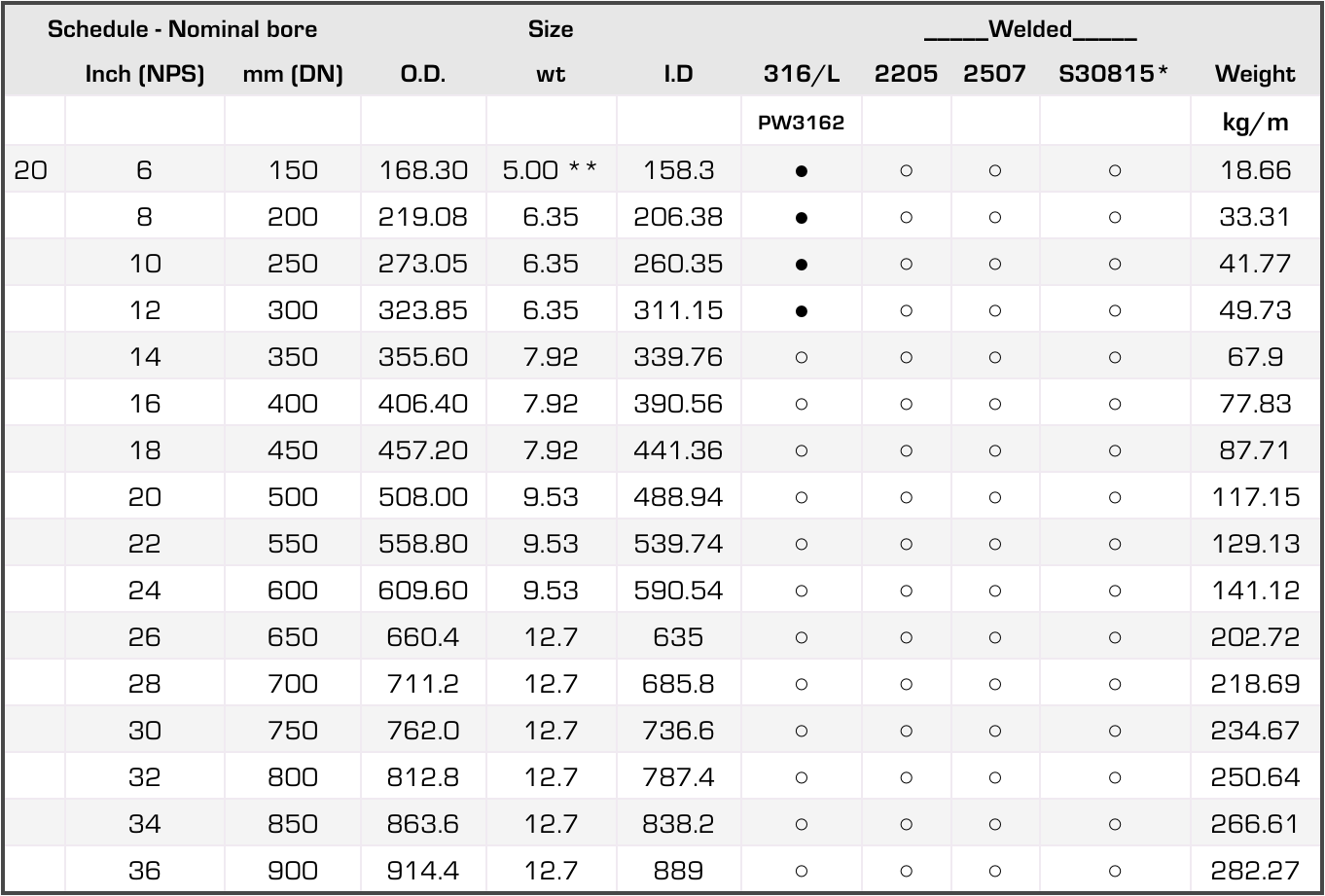

Schedule 20 Pipe Dimensions

Schedule 20 Pipe Dimensions, from 6 inches to 36 inches in thickness.

● Stocked Item ○ Market Available

** Stirlings Spec -0% / +10% WT tolerance

Click here for our full Spec Sheet.

To learn more about our water bore supply solutions, our Schedule 20 range and to make your order, get in contact here!

A rhyme for your time

For water bores you need Schedule 20, come down to Stirlings, we have plenty!

Sources