Dow’s Point Henry coatings plant wastewater system upgrade

The Dow Chemical Company, a global chemicals manufacturer, has completed a major upgrade of the wastewater treatment system at their Point Henry coatings plant in Victoria. The plant manufactures acrylic emulsions which find use in numerous applications including house paints.

Wastewater produced in the production facility is pumped into flocculation tanks for settling and the clear supernatant is sent for further biological treatment. This treated water is recycled back to production but is also used for irrigation on site to minimise freshwater consumption.

Stirlings supplied all Grade 316/L Stainless steel materials to a Dow preferred fabricator for this project, including:

cut-to-length large bore Pipe;

structural rectangular hollow section;

various Pipe fittings;

and Laser/Plasma profiled Plate.

VLocity’s Stainless steel train parts

Image credit: V/Line

Stirlings has supplied Stainless steel key componentry for 27 VLocity trains for Transport for Victoria (TfV) and the Victorian State Government, meeting the demands of the Victorian regional rail network, V/Line.

The VLocity trains safely transport over 1.2 million people in regional Victoria to their destinations every month. They are designed to operate at a maximum speed of 160kp/h and carry over 230 passengers per train; proven components and systems on the fleet ensure high reliability and minimise downtime during maintenance, supporting maximum availability of the fleet for passenger service.

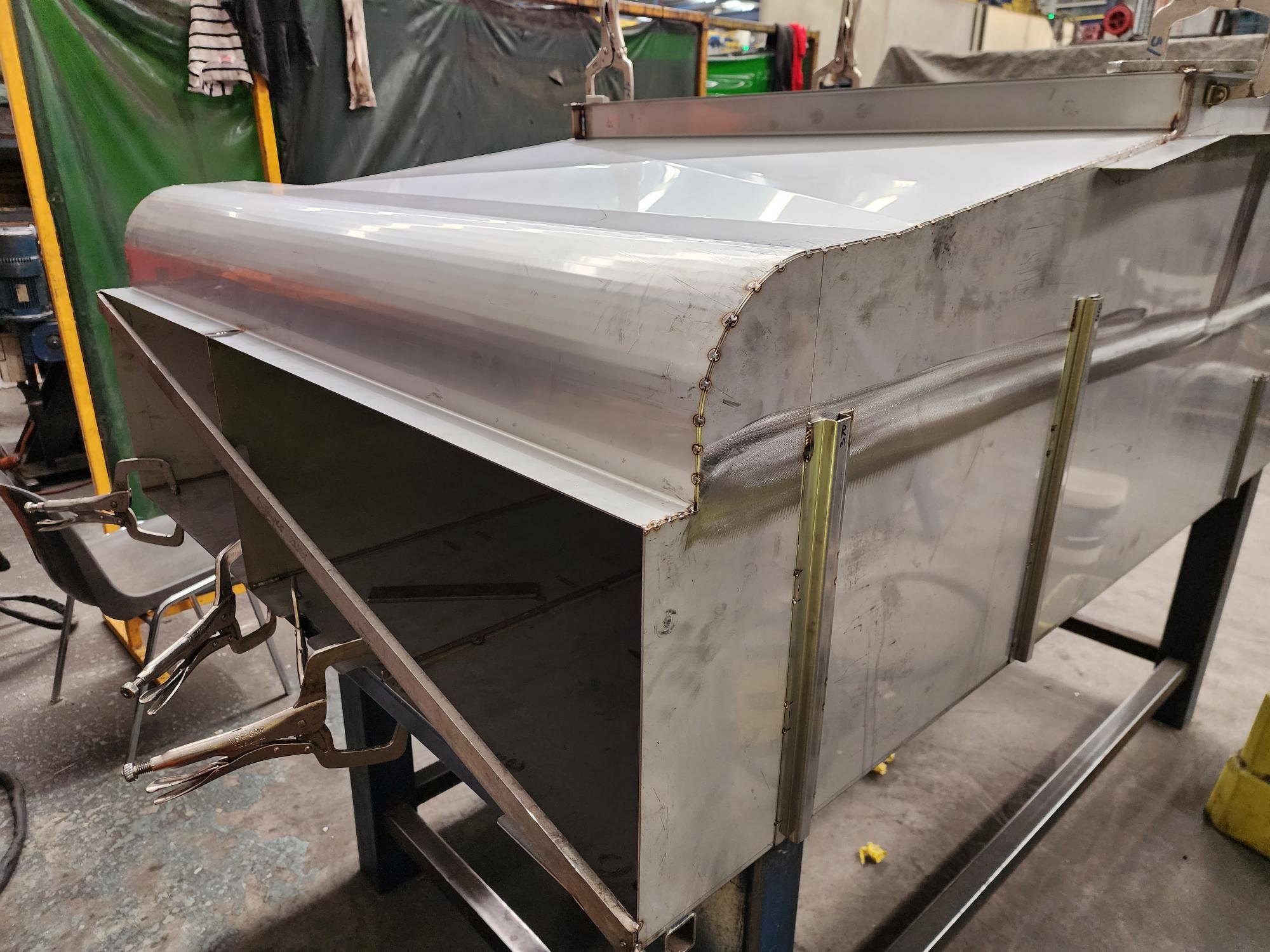

Valued Stirlings customer McMillan fabricated the following parts for the trains:

Fuel Tanks;

Battery Boxes;

Waste Tanks;

Service Ducts;

And Engine Mounts.

Used in their construction were Stainless steel Laser cut Sheet & Plate, RHS, Round Bar, Hollow Bar, Pipe and Fittings supplied by Stirlings.

TFG’s Silicon Carbide filtration skid

Image credit: TFG

Valued Stirlings customer TFG Group Pty Ltd, in collaboration with AquaVoda, has developed a 0.1 micron silicon carbide filtration skid designed to remove 100% of suspended solids and 99.99% of bacteria, which will be used to filter oily wastewater.

The feed permeate output is clean and clear water, which can be easily re-used for a range of different applications. What’s left is a highly concentrated waste output, which can be safely and economically disposed of. With a typical recovery of 95L of clean water output for every 100L of dirty feed water input, this is a highly efficient process, and this particular skid will filter between 2,500 – 5,000L per hour of oily waste water, or up to 25,000L per hour of ground water.

Stirlings supplied Grade 316 Stainless steel Tube, Fittings and Flanges for this project.

Back to projects

AGL’s Torrens Island Energy Storage Facility

Technology group Wärtsilä has completed construction on energy company AGL’s Torrens Island Grid Scale battery energy storage system (ESS). The 250-megawatt (MW)/250 megawatt-hour (MWh) ESS installed at Torrens Island in South Australia is the second-largest operational battery in Australia.

The project delivers a major step towards Australia’s renewable energy future, supporting decarbonisation goals. The ESS will provide enough electricity to power approximately 75,000 South Australian homes for one hour, with the potential to extend the duration to four hours in the future.

Stirlings supplied Stainless steel Grade 316/L Plate, Pipe and Fittings for this project.

BHP Billiton’s Olympic Dam

BHP Billiton’s Olympic Dam is one of the world's most significant deposits of copper, gold, and uranium.

Located 560 kilometres north of Adelaide, South Australia on the traditional lands of the Kokatha, Dieri, and Arabana people, Olympic Dam operates a fully integrated processing facility from ore to metal.

Stirlings supplied Grade 2205 & Grade 316/L Stainless steel Pipe, Fittings, Flanges and Plate for this project.

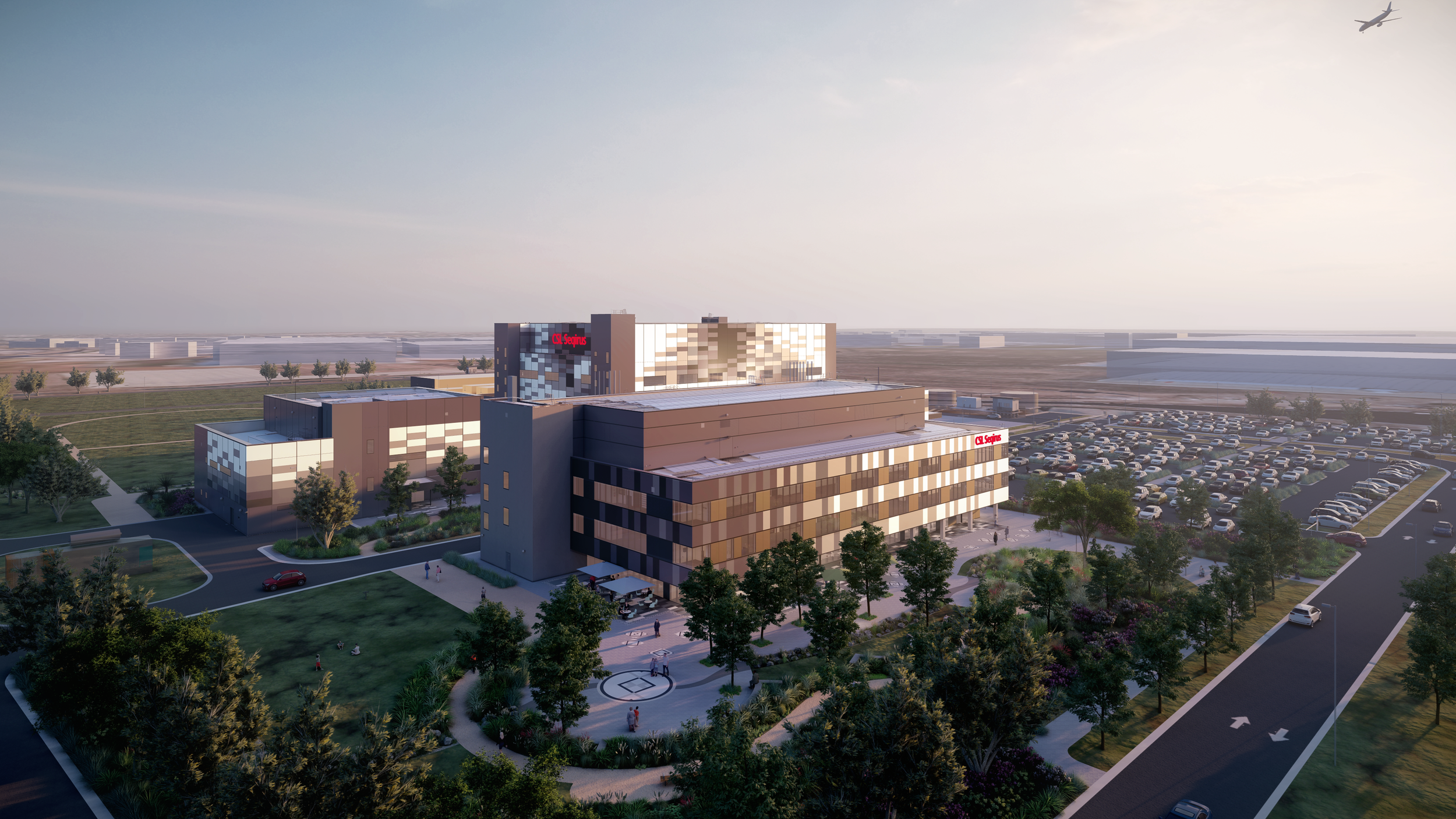

CSL Seqirus

Stirlings is proud to have supplied a significant portion of the pharmaceutical standard Stainless steel for use in the construction of CSL Seqirus, a new state-of-the-art vaccine and anti-venom manufacturing facility in Tullamarine, Victoria!

The project is on schedule to be operational in 2026; and will be used for seasonal and pandemic cell-based influenza vaccine manufacturing, antivenoms, Q-Fever vaccine manufacturing, administration, and laboratories.

The project, by nature of both the application and needs of CSL Seqirus, demanded an accomplished and unwavering supply partner – Stirling’s extensive experience in sourcing, packaging and logistics management for blue chip projects around Australia was put to good use.

Stirlings supplied over 9,500 metres of Tube and more than 29,000 Fittings in ASME-BPE SF1 mechanical polish, ASME-BPE SF4 electropolish and AS1528 in Grades 316/L and 904L in sizes from ¼” to 8”.

ASME-BPE Pharmaceutical materials were sourced from multiple Stirlings strategic supply partners. Supplied to CSL Seqirus via 58 shipments, every part was diligently checked and recorded in our Hallam facility in Victoria. Additionally, Stirlings provided extensive documentation & control to ensure full material traceability.

Altona Pier upgrade

The stunning and historical Altona Pier has completed it’s revamp and is now open to the public!

Located in Bunurong Sea Country in the western suburbs of Melbourne, the circa 1800’s pier now features a spectacular Y-shaped walkway that stretches 300 metres into the sea.

For a valued Victorian customer, Stirlings supplied the following Stainless steel for this project:

630 metres of 32Nb Schedule 40 Grade 316 Pipe;

1,248 metres of 25Nb Schedule 40 Grade 316 Pipe.

All Pipe was polished to 320 grit & electropolished with drilled holes for light fittings.

Stirlings also suppled 330 Stanchions (16mm Grade 316 Plate) Laser cut, polished to 320 grit & electropolished.

Coopers Brewery’s Stainless steel fence

We have supplied top quality Grade 316 Stainless steel for the complete fence around the Coopers Brewery site in Regency Park, South Australia.

The fence will be manufactured with the following products, supplied by Stirlings:

15,000m of 16mm Grade 316 Round Bar;

2,600m of 50mm x 25mm x 1.6mm Grade 316 Rectangular Tube (mirror finish);

905m of 101.60mm x 3.0mm Grade 316 Round Tube x 4,525mm long (600 grit).

The fabrication of the fence has been undertaken by Coopers Brewery’s own workshop located on site at Regency Park, with the fence approximately 1,000m in length. It will be completed by approximately mid-2024.

The fence is to surround a $50 million investment into a brand home that will house a microbrewery, whisky distillery, restaurant & bar.

Jordan Sprigg’s animal sculptures with Stainless steel accents

Stainless steel’s excellent malleability and shine makes it a striking addition to these magnificent sculptures, constructed with recycled rusted metals!

These animal sculptures, by West Australian sculptor Jordan Sprigg, are the following:

Sudan (2020) - an endangered White Rhino

Image credit: Jordan Sprigg Sculptures

The Angus Bull (2021)

Image credit: Jordan Sprigg Sculptures

The Greater Kudu (2022)

Image credit: Jordan Sprigg Sculptures

Blackstar Fabrication created the Stainless steel accents on these brassy beasts from Grade 316 Stainless supplied from Stirlings.

Gage Roads Brewing Co

Gage Roads Brewing Co is a proudly West Australian and independent brewery with more than 14 million litres being sold nationwide every year. This iconic local brand opened its doors to its Fremantle brewpub in 2022, built inside the historical A Shed at Victoria Quay, welcoming locals and tourists in their thousands.

Located on the Walyalup Waterfront, the100-metre-long former cargo shed, originally built in 1926, now contains a 25-hectolitre, 16 tank brew-kit, crafting the full range of Gage Roads beers on site.

Stirlings supplied AS1528 Tube & Fittings, Welded Pipe & Fittings, Flat Bar, Angle Bar and SHS for this mighty project.

Blackstar Fabrication’s handcrafted Stainless steel rose

Image credit: Blackstar Fabrication

This incredible sculpture by Blackstar Fabrication was constructed using Grade 316 1.5mm Mirror polished Stainless steel sheet supplied by Stirlings.

Landcom’s Christopher Cassaniti Bridge

Image credit: Landcom

The spectacular Christopher Cassaniti Bridge (formally the Lachlan’s Line Bridge), located in New South Wales, is ones of Australia’s most innovative and striking new structures.

Commissioned by Landcom as part of the Lachlan’s Line Precinct development project connecting north-west Sydney suburbs Macquarie Park and North Ryde, this design is the first of its kind in Australia. Utilising a double helix arrangement with a varying diameter along its curving 178m length, at its narrowest it is 5.5m and reaches 7.8m at its widest. This incredible structure provides visual flair, safe accessibility, and excitement to the typically heavily traffic-congested area with a promotion of reduced car dependency, creating a significant positive impact to the surrounding environment.

Fabricated by New South Wales customer S&L Steel, Stirlings Performance Steels supplied around 100 tonnes of high-grade 2205 Duplex grade Stainless steel for the project. 2205 Duplex grade presented as an ideal material, thanks to its hybridised microstructural properties granting it superior mechanical properties to many forms of mild and Stainless steel, as well as offering advantages in durability and low maintenance due to its superior corrosion performance.

Austal’s Cape class patrol boats

Image credit: Austal

The Cape class is a ship class of 20 large patrol boats operated by the Marine Unit of the Australian Border Force, the Royal Australian Navy and the Trinidad and Tobago Coast Guard.

Designed and manufactured by long-time valued customer Austal, these striking 58.1 metre mono-hull aluminium patrol boats with a displacement of 400 tonnes are able to:

Reach a maximum speed of 25 knots (46km/h);

Undertake 28 day patrols, in conditions up to Sea State 4;

Sail 4,000 nautical miles (7,400km) at 12 knots (22km/h) before having to refuel;

Combat the full range of maritime security threats; Carry a larger crew to more effectively and safely manage boarding operations;

Identify, track and intercept an extended range of threats in the maritime domain and gather intelligence and store evidence for matters that may proceed to the courts;

and Launch two Tender Response Vessels simultaneously.

For these remarkable naval vessels, Stirlings Performance Steels supplied a large range of Pipe, Tube Fittings & Flanges, Seamless Tubes, Pressfit products, Bar products, Valves and Plate & Sheet products made of Stainless steel, Duplex Stainless steel and Copper Nickel for various specialty purposes.